The Power 40, 50, 80 and 100 units are designed for cable diameters of up to 132mm/ 5" inch.

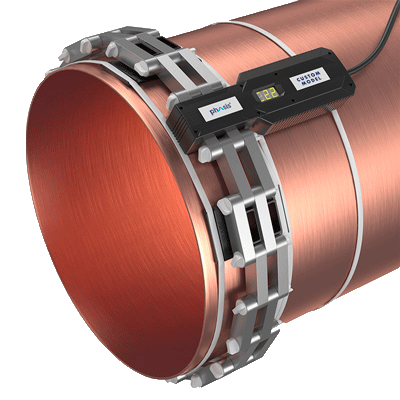

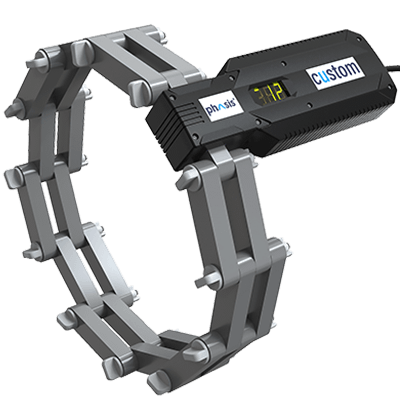

The custom units (see below) cover cable diameters up to 355.6mm/ 14" inch.

The Custom XL units are equipped with two independent induction sources and cover larger water pipe dimensions from 14" inch upwards.

Phasis Power is suitable for all industrial drinking and process water circuits. Common applications are:

Custom XL

From 16" upwards

Up to 135 Volt Induction power

Technical data

Custom made

6" | 10" | 12"

Up to 135 Volt Induction power

Technical data

Phasis...

... prevents scaling without the use of chemicals and additives

... significantly reduced cleaning times and prevents long downtimes and production losses

... increases performance industrial process heat and prevents heat loss

... extends maintenance intervals and reduces maintenance costs

... acts against biofouling in cooling towers

... is gentle on materials and increases the service life of technical equipment

... counteracts calcification, siltation and blockages

... systems are maintenance-free, fully automatic and conform to IP 65

Heat exchangers are widely used in today's industrial and building services engineering and provide high efficiency and optimum operation. Plate heat exchangers in particular are susceptible to impurities such as lime or sludge due to their design. Even small deposits on the heat exchanger plates can result in an enormous loss of performance or even cause a complete failure of the system unit.

High flow temperatures and possible operating faults are the result of scaling and blocking.

Due to their extremely strong induction feed, the Phasis units are able to avoid these scale deposits and fouling or to significantly increase cleaning intervals. Efficiency and energy efficiency are optimised. The Phasis units work maintenance-free, fully automatically and without additives, which means a relief for the maintenance management.

Phasis is mounted directly in front of the heat exchanger on the pipe. The feeding of alternating current pulses of up to 100 volts into the line takes place inside the ferrite ring. This is where the strong electric field is built up. Due to the conductivity of the water, this high-frequency voltage is transferred to all areas of the water network including the heat exchangers.

The frequency of the Phasis devices is almost 50,000 times faster than our normal alternating current. The constant rapid succession of these impulses causes the limescale-forming elements magnesium and calcium to split into tiny microcrystallines and, due to their surface structure, are no longer able to form calcifications.

The strong alternating current signals are decisive for combating algae, bacteria and biofilm. The osmotic pressure generated in the cells causes them to burst and die. The bactericidal effect improves water hygiene.

In addition to many years of experience in water treatment and protection against lime in large properties,

Our customers include companies in the food industry, waste water treatment, mines, wood and plastics industry, electroplating, etc. The realisation of limescale protection systems in demanding pipeline systems is one of our daily tasks. Talk to our technical consultants and engineers about your objectives. A test operation of a suitable Phasis Power system in your company is generally recommended.